Electrical Testing

Continuity, Function, and Electrical Testing Systems

LM3’s Electrical Testing Systems are designed to validate the continuity, resistance, short circuits, and signal integrity of electromechanical and connectorized components during production. These systems are powered by our PAQi controller and integrate high-speed electrical probes, signal generators, and programmable logic to automate the detection of open circuits, cross-wiring, and incorrect pin assignments. Built to handle high-mix, high-throughput operations, they ensure every part meets electrical compliance before reaching downstream assembly or packaging. Designed for standalone operation or integration with vision inspection and traceability systems, these test stations help prevent field failures and warranty risks.

System Features

_edited.png)

Custom Test Connectors

Precision-designed electrical interfaces tailored to fit and test unique part geometries and contact configurations.

_edited.png)

Full Function and Electrical Testing

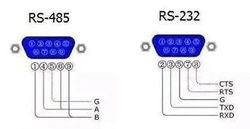

Interfaces with test systems over protocols like CAN, LIN, Modbus, and Ethernet/IP, coordinating measurements and pass/fail.

Custom Test Cables

Engineered cable assemblies and mechanical fixtures ensure secure, repeatable connections during high-speed testing.

Integration Points

|

|---|

|

|

|

|

Technical Details

System Features

PAQi Electrical Testing integrates digital continuity and resistance testing with vision-based validation to ensure critical components meet electrical specs. Systems are fully configurable for high-mix production and can combine mechanical test fixtures with multi-channel instrumentation and MES connectivity.

Metric

Range

Details

Continuity Range

Resistance Range

Voltage Range

Inspection Cycle Time

Trigger Method

Output Format

Data Logging

Part Presentation

0 – 10 Ω

0 – 1 M Ω

0 – 48V DC

2 – 6 sec

Operator Start / PLC Command

Test Report + Pass/Fail

Enabled

Fixtured or Manual

Adjustable threshold limits based on test profile

Capable of fine resistance validation

Available for active circuit validation

Depends on total number of points tested

Manual or automated triggering options

Flexible setups based on production needs

Includes full test matrix if desired

Full traceability with timestamped result records