PAQi P&P

Vision-guided Robotic Pick and Place

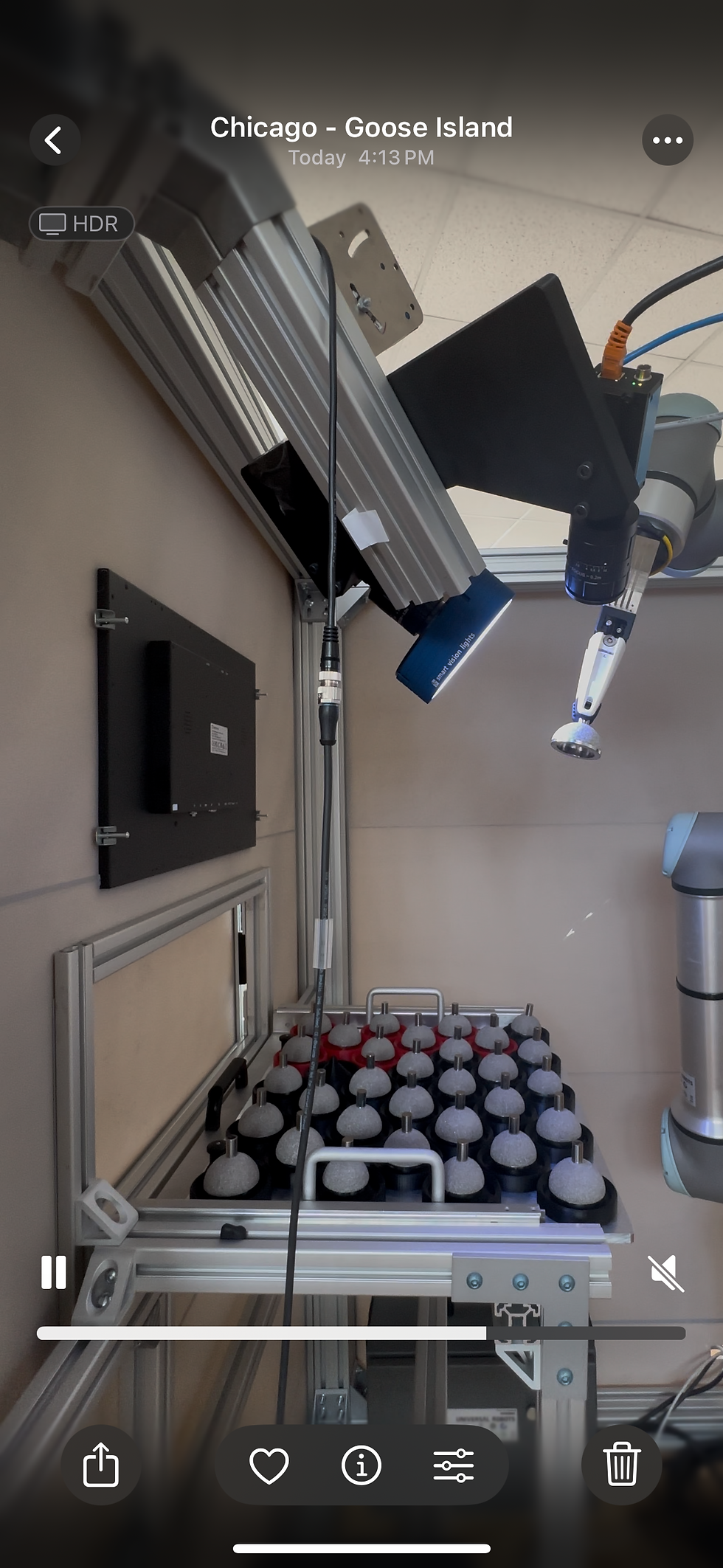

LM3’s Pick and Place Systems are engineered to automate the movement, orientation, and placement of parts using AI-guided vision and robotic actuation. Whether it’s bin picking, precise placement in trays or fixtures, or transferring parts between production zones, these systems bring speed, repeatability, and smart decision-making to high-throughput environments. Integrated with our PAQi vision controller, they identify part position, orientation, and quality before initiating movement, ensuring that only good parts proceed and reducing costly errors and cycle time.

System Features

_edited.png)

PAQi Controller Unit

Executes vision-guided movements, synchronizing robot commands with real-time 3D image analysis and communication.

SICK PLB Series

3D vision system for precise localization and guidance of randomly placed parts in bin-picking and dynamic placement tasks.

Robots

Integrated robotic arms deliver high-speed part handling and placement with coordinated motion tied to vision feedback.

Technical Overview

System Capabilities

PAQi Pick and Place systems integrate vision-guided robotics and part localization software to enable dynamic part handling. Using calibrated vision and 3D cameras, the system supports bin picking, conveyor tracking, and precise part placement in real-time with minimal human input.

Integration Points

|

|---|

|

|

Metric

Range

Details

Camera Resolution

Inspection Cycle Time

Targeting Accuracy

Lighting Requirements

Part Handling

Trigger Method

Output Format

Data Logging

5 MP – 42 MP

< 1 second (vision targeting)

± 1–3 mm typical

Integrated / Overhead Lighting

Bin, Tray, Conveyor, Fixed

PLC / Robot / Sensor

Pick Coordinates / Orientation

Enabled

Higher available for precision pick tasks

Robotic motion cycle is separate

Depends on camera height and calibration

Adjustable to minimize shadows and glare

Designed for varied presentation methods

Triggered when pick position needed

X, Y, Z, and rotation relative to robot TCP

Optional pick and placement event tracking